Laser Cutter Series

ADVANCED LASER CUTTING OF PRINTED FABRICS AND TEXTILES

Our specialists in laser cutting technology have over 25 years of experience. The knowledge gained during this time, combined with market feedback led to further development and optimization of Summa's laser machines.

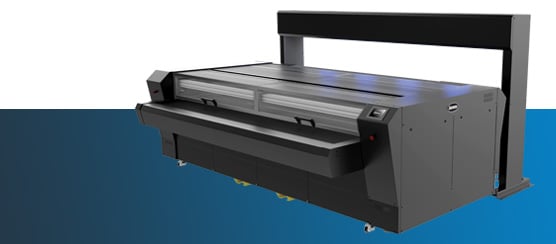

Now about to introduce the L1810 second generation. Discover the L Series optimised for cutting printed fabrics and textiles.

Optimise your workflow with

laser cutting technology

Whether you are in the industry of fast fashion, sportswear or technical textiles, the L Series serves as a perfect laser cutting system optimised for textile cutting.

5 Pillars of Summa Laser Technology

Today’s laser equipment from Summa is a result of continuous research and further development of earlier products. Technology has evolved and modern laser systems are safer, more productive and easier to use. Summa laser equipment is based on the following 5 most important pillars:

- Power. With Summa OptiPower technology the laser beam remains focused and constant, guaranteeing a consistent cutting result over the complete cutting surface

- Precision quality. The concentrated power of the laser on a very small focal spot size, allows the laser cutter to cut designs with the highest precision and leave edges soft without fraying

- Class 1 Safety. Summa laser cutters are classified for Class 1 safety with a closed cover system and thorough extraction of fumes

- Stability. The chassis of Summa laser cutter L1810 is made from welded steel, making it incredibly stable, resulting in a high level of accuracy

- Productivity. The highly performant Summa laser cutters can boost productivity thanks to smart features such as the optional Vision System and many convenient media handling options

GoProduce Laser Edition cutting software

The L Series range comes with the dedicated and production-oriented GoProduce Laser Edition software, developed to handle jobs easy and efficiently whilst optimally using materials. The software includes several smart, easy-to-use options and features to establish an automated workflow where operator comfort is key. For instance, the Barcode functionality, Pro feature, allows to automatically process an entire roll of textile with different cutting jobs, without operator intervention. Read more

ApS-Ethos Laser Cutting and Engraving software

If you own a previous Summa (FB) laser cutter with the ApS-Ethos Laser Cutting and Engraving software installed, you can find more information about this software here.

Laser camera technology

The Summa laser cutting machines are equipped with unique camera technology, where you can choose which method is most suitable for your specific type of job. There are two types of camera available: the Vision Camera (standard on the L3214) and the Head Camera (standard on the L1810, upgradable to a Vision system).

Vision Camera System

The Vision system represents ingenious camera technology, designed to give your productivity a big boost. Pinpoint Vision camera recognition scans the material meticulously, so there is no room left for errors.

Workflow efficiency is obtained through different possible cutting methods, tailored to your specific cutting needs and taking into account the desired production volume.

- Cut-on-the-Fly, meaning the Vision system allows to feed, scan and cut each material segment simultaneously

- Cut-to-Frame, allowing to process jobs that require a fixed size to fit perfectly into SEG frames

- Trace & Cut, tracing the contours of the design without prior cutting data. Very convenient method when cutting sportswear.

- Barcode (Pro Pack needed), powerful workflow automation that frees up operator time to attend to other assignments

Head Camera System

The head camera system is standard mounted on the L1810 laser cutters and optional on the FB Series. This camera system uses registration marks to process cut-to-size, as well as contour cutting jobs.

Increased accuracy and advanced nesting capabilities not only ensure a clean-cut but also reduce material waste substantially.

Combined with the GoProduce Laser Edition software, the Head camera system allows using the following cutting technologies:

- Cut-to-Frame, allowing to process jobs that require a fixed size to fit perfectly into SEG frames

- Barcode (Pro Pack needed), enhancing workflow automation and productivity to the maximum, so the operator can free up time to attend to other assignments

The game-changers in textile manufacturing

Laser cutters within the L Series are available in two models for which you can choose the power and many more options you need. These L Series models are optimised for cutting fabrics.

MODEL L1810

SPORTSWEAR - DYE SUBLIMATION

Seamlessly meet requirements for cutting textiles

- Especially suited to cut textiles

- Ability to cut all sorts of raw materials

- Standard equipped with head camera

- Vision system is optional

- Suitable for high-production environments

- Fast processing for more throughput in less time

MODEL L3214

SOFT SIGNAGE - LARGE-FORMAT

Meet your customers' deadlines and improve your margin

- Standard equipped with Vision camera

- On-the-fly cutting: cutting while scanning in the next part, simultaneously

- Edge-detect de-reeler ensuring a straight feed of the material

- The camera scans registration marks or contours using trace

- Automatic creation of cutting vector

- Suitable for high-production environments

- Cutting typical jobs at 400 m²/hour

FB Series - Laser Cutting Systems

Contact us for a cutting solution for your industrial applications.

In addition to the L Series, Summa offers FB Series laser cutting machines for highly specialized and industrial applications.

The systems are developed by Summa's laser division CadCam Technology. Our laser division has over 25 years of experience in laser cutting technology. The knowledge, gained over the years, combined with market feedback led to further development and optimization of our laser cutting machines.

| MODEL: | L1810 2nd generation |

L3214 |

| LASER POWER | 50 or 100 Watt (Aircooled) 120 or 250 Watt (Watercooled) |

250 Watt (Watercooled) |

|

DIMENSIONS (H x W x D) |

1172 x 2810 x 2178 mm |

2135 x 4382 x 3800 mm |

| MEDIA WIDTH | Up to 1845 mm | Up to 3400 mm |

| WORKING AREA | 1840 mm x 950 mm | 3300 x 1400 mm |

| SPEED | Up to 1000 mm/s | Up to 1500 mm/s |

| ACCELERATION | Up to 1G | Up to 1G |

| CAMERA RECOGNITION |

|

|

| FEATURES |

|

|

| STANDARD SOLUTION INCLUDES |

|

|

| OPTIONS |

|

|