Flatbed Cutter Series

The most versatile flatbed cutting system ever

Summa’s professional Flatbed Cutting System is an innovative solution for producing a broad variety of signage, displays, samples, packaging applications, and more.

Built to grow with your business

With an ever-increasing arsenal of tools and optional add-ons, the F Series flatbed cutting system is the breakthrough cutting solution you’ve been dreaming about.

MEET EVERY NEED OF YOUR CUSTOMER

Your range of applications is endless with the F Series. Enjoy industry-leading features and optional add-ons.

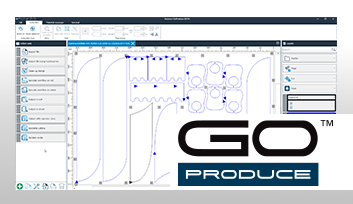

GoProduce software to perfectly match your F Series

The software GoProduce is developed to handle jobs easy and efficiently. The modern interface with improved navigation enables users to find and operate functions as quickly and intuitively as possible.

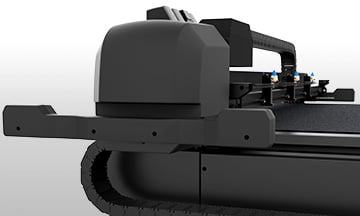

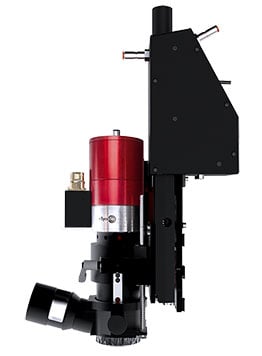

Multifunctional cutting head for cutting efficiency

The multifunctional head can hold up to three modules at one time. The central unit houses a positioning laser and an integrated camera system for fast and accurate contour-cutting mark recognition.

Tangential Module for power and precision

Offering a vertical force of 10 kg and corresponding to a wide range of matching tools. Each tool has a barcode identifier, ensuring automatic recognition and parameter settings.

Advanced Safety System

The advanced Safety System, delivered with all F Series models, guarantees a safe work environment and is compliant to worldwide health and safety requirements. Thanks to the placement of the system on the top beam, the F Series can be accessed easily, which results in higher production efficiency.

Barcode for Automated workflows

The barcode automatically identifies the job to obtain the necessary cutting data from the computer. The built-in camera scans the job automatically or by a hand scanner, depending on the selected workflow.

Automatic Depth Control (ADC)

The ADC automatically sets the knife depth and the orientation of the tool. The tip of the knife or bit is measured accurately and the down position of the tool is set to table's level, guaranteeing a flawless cut. Both the ADC left and ADC right is included with every new F Series flatbed cutter.

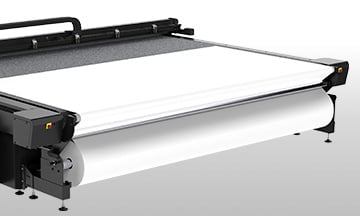

Conveyor extension to minimize downtime

The conveyor extension, optional on the F1612 flatbed cutter, processes cut designs that are much larger than the actual cutting area. While the machine cuts the next part, the first cutout parts can be removed safely at the extended front.

Note: image to be updated to F1612 with safety system.

Accelerated workflow with F-Performance

Increase the performance of your F Series flatbed system with almost 40%. Advantages include faster up, down and turning movements of the cutting head, which will be most remarkable when using the Kiss-cutting tool.

Heavy-Duty Roll Support

The optional Heavy-Duty Roll Support allows a straight throughput of print rolls onto the wide-format flatbed sizes, F1832, F3220 and F3232. For the processing of heavy banner material and light to non-stretchable wide textile rolls, this roll support will facilitate the operator’s life considerably.

CHOOSE YOUR SIZE OF VERSATILITY

Cutting tables are available in five models. Each of them is bound to significantly increase your productivity.

MEDIA HANDLING HAS NEVER BEEN EASIER

The extensive range of media handling solutions helps you to work precise and more efficiently.

- The advanced Safety System guarantees a safe work environment. Convenient placement on the top beam ensures easy accessibility of the flatbed to remove cut parts.

- Media Advance Clamps hold the material down while pulling it forward in order to work continuously in panels or multiple jobs.

- The vacuum pump with sound absorber holds the material in place during the job while the selector adjusts the vacuum automatically to match the working area.

- The Conveyor belt & Roll support allow the cutting and creasing of large lengths of flexible material to large production runs.

- The working area can be divided into two separate zones, a cut only zone and an Operator Zone where materials can be removed with ease.

- The optional Heavy-Duty Roll Support allows a straight throughput of heavy banner material, non-stretchable wide textile rolls and lightly stretchable materials onto the wide-format flatbed sizes F1832, F3220 and F3232. Video Heavy-Duty Roll Support

EXPLORE FURTHER WITH TOOLS

An array of possibilities within every module and tool.

Specifications

Our teams are happy to advise you on a model that suits your business best.

| MODELS: |

F1612

|

F1432 NEW F1330 successor |

F1832

|

F3220

|

F3232

|

| CUTTING AREA | 160 cm (63 in.) wide x 120 cm (47 in.) long; up to 50 m (164 ft.) long in multi-panel | 136 cm (53 in.) wide x 320 cm (126 in.) long; up to 50 m (164 ft.) long in multi-panel | 184 cm (72 in.) wide x 320 cm (126 in.) long; up to 50 m (164 ft.) long in multi-panel | 327 cm (128.7 in.) wide x 210 cm (82.6 in.) long; up to 50 m (164 ft.) long in multi-panel | 327 cm (128.7 in.) wide x 320 cm (126 in.) long; up to 50 m (164 ft.) long in multi-panel |

| MEDIA WIDTH | Up to 165 cm (65 in.) | Up to 142 cm (56 in.) | Up to 190 cm (75 in.) | Up to 332 cm (131 in.) | Up to 332 cm (131 in.) |

| MULTI PANEL* | 5000 cm (1968 in.) *Media clamps and roll-feed and/or conveyor belt system are required |

||||

| REPEATABILITY | Within ± 0.05 mm on plots | ||||

| ACCURACY | 0.05 % of move or 0.05 mm, whichever is greater | ||||

| SPEED | Up to 1000 mm/sec (39.4 in./sec) | ||||

| ACCELERATION | Up to 1 G | ||||

| CLEARANCE* | 5 cm (2 in.) *Distance between vacuum table and Y-beam. Not taking into account the thickness of a cutting mat or conveyor belt |

||||

| MAXIMUM ALLOWED FORCES | Vertical: 200 Newton, Horizontal: 200 Newton | ||||

| MAXIMUM TABLE LOAD | 50 kg/m² (10.2 lb/ft²) | ||||

| CONNECTIVITY | USB | ||||

| POWER REQUIREMENTS | 3 Phase 208V+N or 3 Phase 230V or 3 Phase 400V+N | ||||

| DIMENSIONS | 247 x 220 x 110 cm (97 x 86 x 43 in.) |

230 x 422 x 122 cm (91 x 166 x 48 in.) |

279 x 422 x 122 cm (110 x 166 x 48 in.) |

422 x 313 x 122 cm (166 x 123 x 48 in.) |

422 x 422 x 122 cm (166 x 166 x 48 in.) |

| WEIGHT | 500 kg (1100 lbs) | TBD | 1530 kg (3375 lbs) | 1760 kg (3883 lbs) | 1974 kg (4347 lbs) |

| OPERATING TEMPERATURE | 15˚ to 35˚C (59˚ to 95˚F) | ||||

| STANDARD ACCESSORIES | Drag Module, Conveyor System, Roll-Feed System, Safety System 2020, Pneumatic Pack, ADC left&right, standard 36˚ blade holder, 1 standard blade, 1 fiber-tip pen, hex screwdriver (4mm), hex screwdriver (2.5mm), USB cable (3 meter), USB extension cable (0.5 meter), media guide flanges (set of 2), Summa GoProduce software. | ||||

| OPTIONAL ACCESSORIES | Tangential Module, F Series Routing System, HF Routing System, HT Rotary module, Electronic Oscillating Tool, Pneumatic Oscillating Tool, Kiss Cutting Tool, Single Edge Cutout Tool, Double Edge Cutout Tool, Heavy Duty Cutout Tool, Creasing Tools, V-Cut Tools, production software, basket (F1612), extension tables (F1612), wireless controller w/charger. | ||||